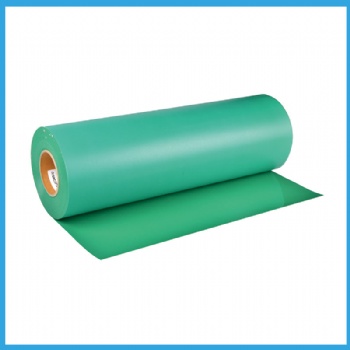

DETAILS

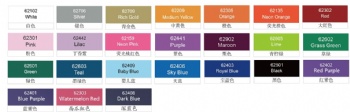

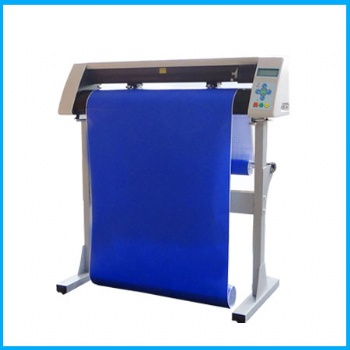

PVC heat transer vinyl use process:

1. Fix the heat transfer vinyl on the pad with the PET film facing down and the pu film facing up.

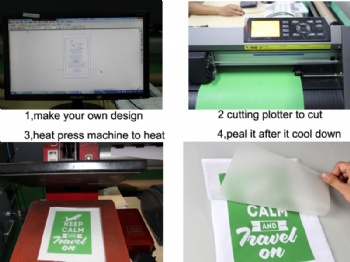

2. The position of the cutting plotter is transferred to iron on.

3. Design patterns on the computer. The patterns must be mirror images.

4. Use a cutting plotter to cut into the desired shape first, and use a tweezers to remove the film outside the pattern.

5. First iron the fabric with an iron. The iron is set between wool and cottonfor 30 seconds. Cover a layer of Teflon cloth to protect your clothing

6 Make sure that each place is heated,peel off the PET film when done.

note:

1 Our HTV is suitable for ordinary cutting plotters and laser machines

2 The back of our HTV is sticky and can restore lines or patterns.

3Heat transfer temperature between 130-160ºC,Therefore, it is not suitable for down jackets and silk fabrics.

4 It is suitable for synthetic fabrics such as cotton, hemp, and spandex, not suitable for black polyester fabrics. If you are in a fabric with a special material such as a waterproof coating, you can test it in a small area.

5 heat transfer vinyl is suitable for use on fabrics, not for glass, metal, ceramic tiles.

Suggest:

After testing, we found that

1 If you are using a cricut machine, it is more appropriate to adjust the machine to the iron-on position.

2 If you use a cameo machine, silhouette ratchet blade 1, speed 10cm/s.

3 Use household electric irons (not suitable for steam irons), and iron them back and forth for 20S-30S to make sure that each part is hot.

4 If your fabric is a high-grade fabric such as wool, we recommend that you cover a layer of Teflon cloth to protect your clothing.

1. Fix the heat transfer vinyl on the pad with the PET film facing down and the pu film facing up.

2. The position of the cutting plotter is transferred to iron on.

3. Design patterns on the computer. The patterns must be mirror images.

4. Use a cutting plotter to cut into the desired shape first, and use a tweezers to remove the film outside the pattern.

5. First iron the fabric with an iron. The iron is set between wool and cottonfor 30 seconds. Cover a layer of Teflon cloth to protect your clothing

6 Make sure that each place is heated,peel off the PET film when done.

note:

1 Our HTV is suitable for ordinary cutting plotters and laser machines

2 The back of our HTV is sticky and can restore lines or patterns.

3Heat transfer temperature between 130-160ºC,Therefore, it is not suitable for down jackets and silk fabrics.

4 It is suitable for synthetic fabrics such as cotton, hemp, and spandex, not suitable for black polyester fabrics. If you are in a fabric with a special material such as a waterproof coating, you can test it in a small area.

5 heat transfer vinyl is suitable for use on fabrics, not for glass, metal, ceramic tiles.

Suggest:

After testing, we found that

1 If you are using a cricut machine, it is more appropriate to adjust the machine to the iron-on position.

2 If you use a cameo machine, silhouette ratchet blade 1, speed 10cm/s.

3 Use household electric irons (not suitable for steam irons), and iron them back and forth for 20S-30S to make sure that each part is hot.

4 If your fabric is a high-grade fabric such as wool, we recommend that you cover a layer of Teflon cloth to protect your clothing.